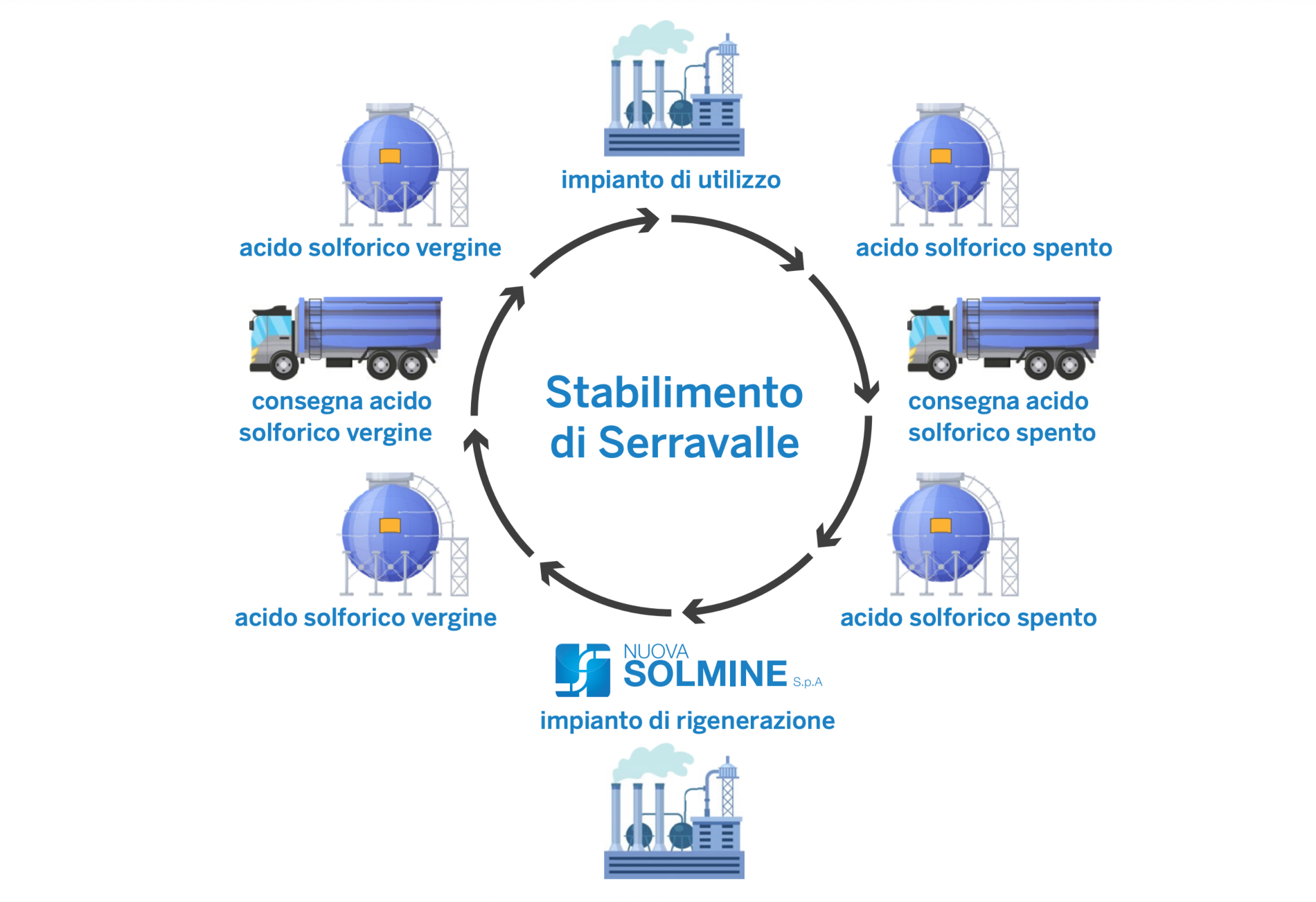

Serravalle Scrivia plant

The plant works in a continuous cycle, thus guaranteeing that clients can deliver their waste products all year round and avoid the typical problems associated with such deliveries to other recycling organisms. The ample stocking facilities available for various types of waste are an added advantage.

This waste and the process sulphuric acids are managed with great care and attention at all times, from acceptance, unloading and stocking through to treatment and final recovery in the two incineration lines: one a static furnace for liquid waste and a rotating drum furnace principally used for solid waste.

The main uses of the waste treated at the Nuova Solmine plant in Serravalle Scrivia are for:

- Chemical industries and plants

- Pharmaceutical industries and plants

- Refineries

- Food farming

- Pickling and metalworking

- Manufacturing intermediate products for chemical farming

- Manufacturing detergents and soaps

- Refining of oils

- Regeneration of spent oil

- Production of explosives

- Gas desulphurisation processes

- Smoke treatment and abatement plants

- Working and refining minerals

- Reclamation of industrial sites

Reclamation and cleaning operations of tanks, and stocking and work areas

The Nuova Solmine plant at Serravalle Scrivia is authorised to carry out stocking, both dangerous and no dangerous industrial waste recovery, in accordance with the Integrated Environmental Authorisation (AIA) issued by the Province of Alessandria (Prot. Gen. 20090043169-DDAA2-74-2009 dated 27/3/2009 and s.m.i.). This authorises the recovery of up to 69,000 tons of both dangerous and no dangerous waste material.

The following are the typologies of authorised waste:

- Liquid waste containing sulphur with no calorific power

- Liquid waste containing sulphur with calorific power

- Solid sulphur waste

- Liquid waste with high calorific power

- Solid waste with high calorific power

The recovery of the sulphur contained in liquid and solid industrial waste, often classified as dangerous, has, in fact, a positive influence on the environment. This is both as a result of the savings in raw materials and, above all, because of the efficient treatment of waste that could otherwise produce a negative environmental impact by developing sulphur dioxide emissions. Such is the case when the waste products and sludge for the dump and those to be neutralised, are incinerated.